Talk to Mark Wortham. I think he had a set of titanium backing plates he needed to modify.

I might be willing to go in on a sheet of titanium. I have a plasma cutter, if that could rough out the shape and then use a grinder to finish it off.

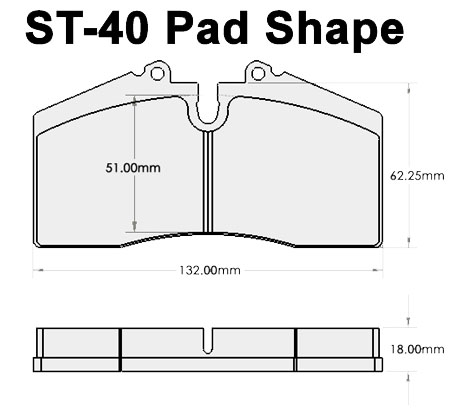

I need to find someone who can cut 4 brake pad backing plates out of titanium. The cut is very simple and I want the plates to be thin. I also need the titanium. Any recommendations?

M3 is always the answer.

Talk to Mark Wortham. I think he had a set of titanium backing plates he needed to modify.

I might be willing to go in on a sheet of titanium. I have a plasma cutter, if that could rough out the shape and then use a grinder to finish it off.

McMaster-Carr has the Ti

http://www.mcmaster.com/#titanium/=acj4o4

I have heard that stop tech recomends against Ti backing plates.

edit

It was carbotech not stop tech

http://www.s2ki.com/forums/index.php?showtopic=831393

Last edited by Robert; 12-28-2010 at 03:27 PM.

Stainless has better heat properties for what you are looking to do.

Stainless is .039 vs ti at .041. The lower the number the better.

Cheaper and easier to machine.

TCB approved.

Thermal Conductivity. The ability of a metal to conduct or transfer heat is called its thermal conductivity. Thus, a material, to be a good insulator, would have a low thermal conductivity, whereas a radiator would have a high rate of conductivity to dissipate the heat. The physicist would define this phenomenon as the time rate of transfer by conduction, through unit thickness, across unit area for unit temperature gradient.

http://www.azom.com/Details.asp?ArticleID=1298

I want to block the heat from cooking the calipers, seals, and fluid on the track. So I am looking to insulate the back of the pad. How would stainless hold up?

M3 is always the answer.

I think that is why the some manufactures use stainless backing plates. I think the real answer here is proper air cooling or larger rotors. The metal plate is not really going to make much of a difference in this problem. Now if the thermo guys want to get out their slide rulers I am sure they can prove it.

I bought my ti shims for the evo from tispeed.com. They were part of a system upgrade, so I can't say how much they helped on their own, but the definitely helped as the seals didn't degrade as fast after the change.

They have them premade for you:

http://hardbrakes.com/index.php?main...products_id=48

ETA: all those with light cars that don't have big brakes that are making heat... ya'll need to back out of this thread. The pads are producing a ton of heat. That heat is going into anywhere it can. The rotor take a ton, the caliper some too. Unfortunately there is DIRECT, UNVENTED contact between the pad and piston on the caliper. The heat going directly from the pad into the piston is cooking the fluid from the inside out and ruining the expensive seals that keep the fluid in the caliper/brake system. Ti shims (and potentially stainless) keep that heat from flowing from the pad into the piston.

The reason you don't want stainless (even though it would be vastly cheaper) is because it's heavier and melts at a lower temperature.

Here's a message from Takspeed:

Hi Folks. This is "Alan from Takspeed". I found this thread when doing a google search. Seems some additional explanation here might be worthwhile.

We use 6AL-4V Titanium Alloy, which is expensive, but has HALF the thermal conductivity of stainless. That's a pretty significant difference, and our major reason for going with the alloy. In addition however, stainless steel has mechanical strength issues at these thicknesses, and would tend to smudge over time. Our alloy shims retain their integrity and can be used over and over again as you change pads (unfortunately for our repeat sales ).

As for the thickness, we went with the thin shims so that they would fit even with new pads after they have been bedded. The shims are designed to fit over the caliper pins so that they can be stacked as your pads wear down, INCREASING the thermal barrier as the pads wear down.

Last edited by goofygrin; 12-28-2010 at 05:14 PM.

I won't argue with brake experts. I am just looking at this from a materials property stand point. Melting point of Stainless is 2750F. If things are that hot you lost the brakes along time ago. Ti is about 3040F.

http://www.engineeringtoolbox.com/me...als-d_860.html

I have to agree with general default about melting the stainless. If it's hot enough to melt stainless whats happing to the rotors.

I have to take the brake experts word on the thermal conductivity. I can not find 6AL-4V in my Machinery's Handbook. Looking at other Ti vs. Stainless some of the alloys are very close and some of them are not. It seems the alloy makes a lot of difference and it not just Ti vs. Stainless. 308 stainless is very close to commercially pure Ti.

McMaster-Carr has the 6AL-4V, it's about $60 for .016in x 6in x 6in.

http://www.mcmaster.com/#6al-4v-titanium/=acl7ek

What are your caliper temps? What pad are you running? Straight or curved vein rotors?

I don't see how you're cooking those brakes enough to kill the caliper.

Last edited by SirHustlerEsq; 12-29-2010 at 03:49 PM.

TXMC: Drinkin, shootin, racin!

I'm wondering if that's why the rims cracked.

I'll give you a couple temps strips and we'll see what those caliper temps are. I ask because not only am I brilliant in general but I thought I was cooking my brakes at ECR last time, it turns out that I was overheating the pad rather than the caliper which stayed at 370*f or less. However if you're overheating a PFC01 there is no hope for you. does your brake duct dump into the hat/hub or does it shoot into the rotor like what most of DFW believes is acceptable? If you're overcooking these brakes, how do the gays at Turner and WC deal with it? I know a few who don't run those dustboots and never have a problem.

I'm also starting to think that a slotted rotor makes a difference, but shooting from the hip on that one. When I had the slotted rotors I didn't leave any white/gray/brown pad material on the rotor, nor did I lose brake torque. With the solid rotors the pad is overheating. I need to call on Hawk on that one. I assume that since most PFC rotors are slotted you might be experiencing the same thing I am.

Edit: Sorry to sound like a know-it-all.

Last edited by SirHustlerEsq; 12-30-2010 at 08:07 AM.

TXMC: Drinkin, shootin, racin!